The evolution of door hinges reflects advancements in materials science, manufacturing processes, and design requirements, moving from simple pivots to sophisticated, specialized mechanisms.

Early Forms of Articulation

The earliest methods for door movement were rudimentary. These included:

- Pivot Systems: Doors often rotated on integral pins at the top and bottom, fitting into sockets in the lintel and sill. These could be made of wood or stone.

- Leather or Hide Straps: Offering flexibility, these organic materials served as simple hinges but lacked durability and strength for heavy doors.

The Advent of Metal Hinges

Metalworking introduced significant improvements in strength and longevity.

Strap Hinges:

Among the first true metal hinges, strap hinges feature long, flat metal plates (straps) that attach to the face of the door and frame. This design distributes the door's weight effectively and was often decorative, particularly with wrought iron.

Butt Hinges:

A more compact and common design, the butt hinge consists of two leaves (plates) joined by a central pin forming a knuckle. Typically mortised into the edge of the door and frame, they offer a neater appearance. Early variations included:

- H-Hinges: Surface-mounted hinges shaped like the letter 'H'.

- HL-Hinges: An extension of the H-hinge, with an additional 'L'-shaped plate extending onto the door face to provide greater support, particularly for wider or heavier plank doors.

Industrial Revolution and Standardization

The Industrial Revolution facilitated the mass production of hinges with increased precision and consistency. This era saw the refinement of existing designs and the introduction of new functionalities.

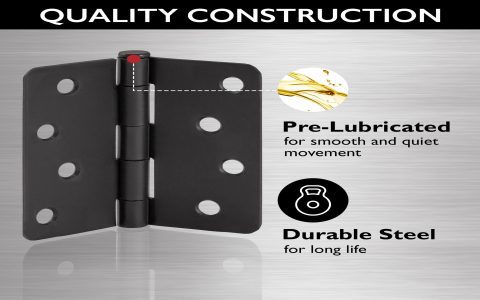

Ball Bearing Hinges:

Developed for smoother operation of heavier doors, these hinges incorporate ball bearings between the knuckles to reduce friction and wear, ensuring longevity and ease of use.

Spring Hinges:

These hinges feature an integrated spring mechanism that automatically closes the door. They are essential for applications like fire doors or doors requiring controlled egress/ingress.

Modern Hinge Innovations

Contemporary hinge technology emphasizes specialized functionality, enhanced aesthetics, and integration with modern architectural styles.

Concealed Hinges (e.g., European Hinges):

Designed to be completely invisible from the outside when the door is closed, these are predominantly used in cabinetry and modern minimalist door designs. They offer multi-directional adjustability (height, side, depth) for precise alignment.

SOSS Hinges:

Another type of invisible hinge, SOSS hinges are mortised into the door and frame and consist of a series of interlocking plates that allow the door to sit flush with the frame when closed, offering a clean, uninterrupted surface.

Modern Pivot Hinges:

While the concept is ancient, modern pivot hinges are sophisticated mechanisms designed for large, heavy, or frameless doors. Mounted at the top and bottom of the door, often offset from the frame, they allow for unique door movements and support substantial weights.

Soft-Close Hinges:

These hinges incorporate a dampening mechanism (hydraulic or pneumatic) that ensures the door closes gently and silently, preventing slamming and reducing wear.

Material science has also played a crucial role, with a progression from primarily iron and bronze to stainless steel, brass, various high-strength alloys, and even advanced polymers for specific applications requiring corrosion resistance, light weight, or non-magnetic properties.