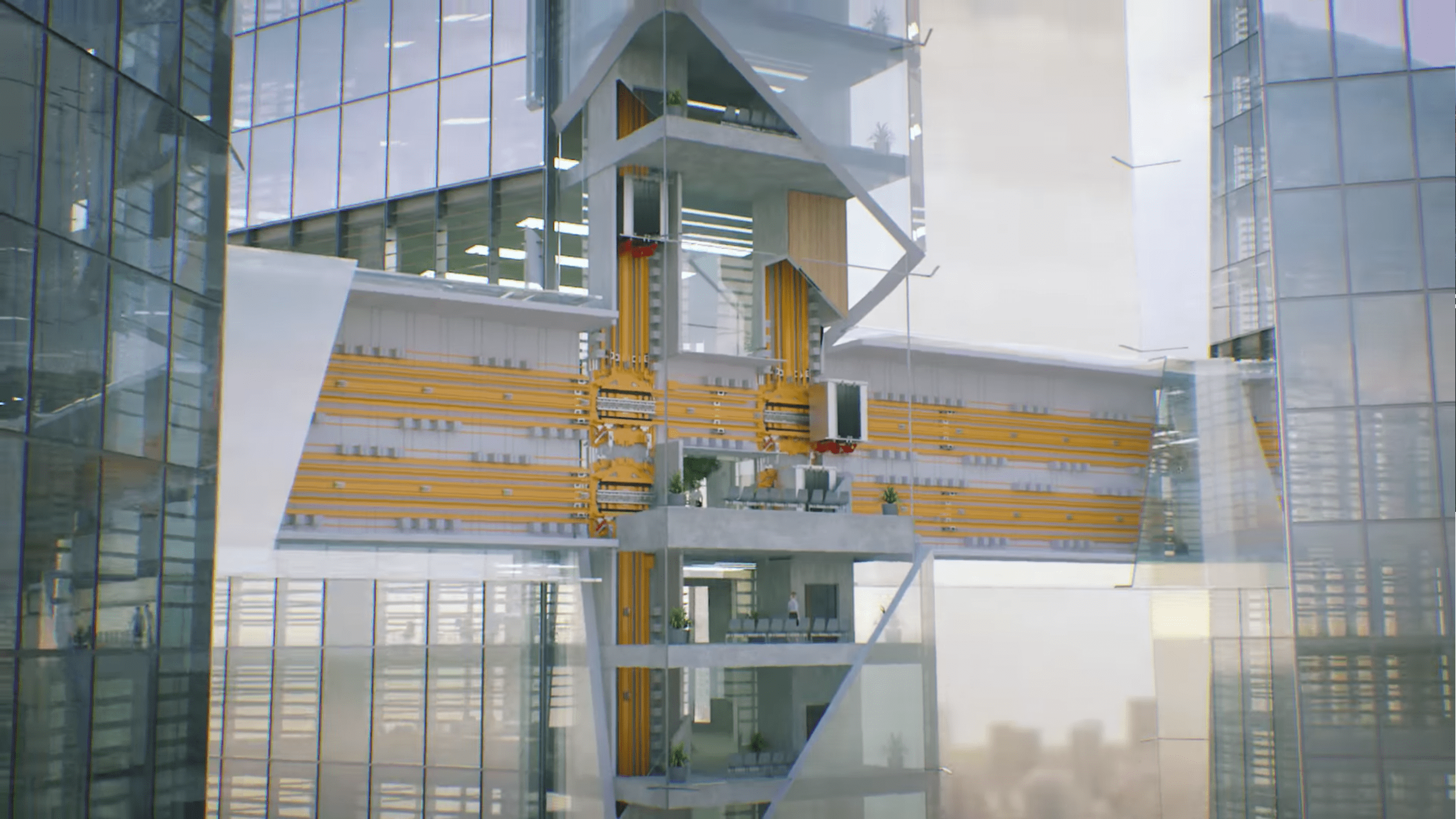

Sideways elevators, also known as horizontal traction elevators, lateral elevators, or trolley elevators, represent a specialized type of vertical transportation system designed to move horizontally within a building structure before ascending or descending vertically. They are distinct from conventional cable-driven or hydraulic elevators due to their unique travel path.

Core Technology and Operation

The fundamental mechanism relies on a horizontally translating platform carrying a vertical elevator cabin. This platform travels along dedicated guide rails embedded in the ceiling structure:

- Lateral Movement Phase: An external drive system (e.g., cogwheel gear, friction wheels, or linear motor track) propels the platform horizontally between designated parking positions above each shaft.

- Vertical Movement Phase: Once aligned above the target vertical shaft, the elevator cabin operates conventionally within that single shaft using standard traction or hydraulic lifting mechanisms attached to the translating platform. The cabin does not move sideways itself; the entire support structure moves.

Key Applications

This technology addresses specific architectural and logistical constraints:

- Space Optimization: Allows multiple vertical elevator cabins to share access to a single, centralized high-rise shaft core, drastically reducing the building's core footprint compared to installing multiple dedicated shafts side-by-side.

- Complex Core Layouts: Enables cabins to serve non-parallel shafts or reach shafts positioned in different horizontal planes relative to the lobby.

- Retrofitting/Historic Buildings: Facilitates elevator installation where conventional vertical shafts cannot be easily added side-by-side throughout the entire building height.

- Inter-Core Connectivity: Can potentially link physically separate elevator cores within a large complex via the horizontal movement path.

Advantages

- Significant Space Savings: Primary benefit, freeing up valuable floor area.

- Increased Passenger Throughput: More cabins can serve fewer shafts efficiently.

- Design Flexibility: Enables unique architectural forms with distributed service points.

Disadvantages and Challenges

- Higher Complexity: Dual movement systems (horizontal translation + vertical lift) increase mechanical complexity and potential points of failure.

- Increased Costs: Higher initial installation cost due to specialized components and complex construction requirements (robust overhead track infrastructure).

- Extended Wait/Travel Times: Horizontal positioning adds an extra step, potentially increasing overall journey duration compared to direct vertical access.

- Maintenance Intensity: Requires specialized expertise and potentially more frequent maintenance for both translation and lift systems.

- Strict Regulatory Compliance: Must meet demanding safety codes (e.g., EN 115-2) for both horizontal and vertical movement phases, including emergency braking and rescue protocols.

Key Considerations

Implementation requires meticulous structural engineering to support the weight and dynamics of the translating platform. Traffic analysis software is crucial for optimizing cabin assignment and minimizing passenger wait times during horizontal transfers. While not common, sideways elevator solutions provide a vital engineering option when conventional vertical core limitations are insurmountable.