Understanding Perforated Metal Facades

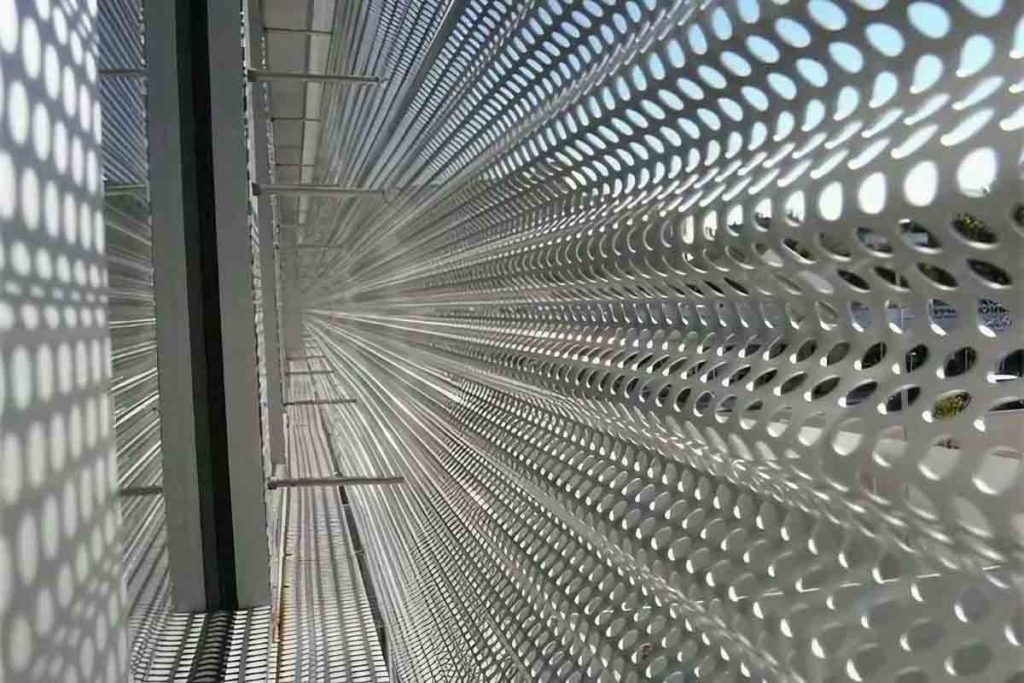

Perforated metal facades are exterior building envelopes constructed from metal sheets or panels that feature a pattern of holes, slots, or other openings. These systems are highly valued for their ability to combine aesthetic appeal with functional performance, significantly influencing a building's visual identity and environmental interaction.

Materials and Manufacturing

The creation of perforated metal panels typically involves processes such as punching, laser cutting, or CNC machining to achieve precise patterns. Common materials used include:

- Aluminum: Favored for its light weight, excellent corrosion resistance, and high formability, allowing for complex designs.

- Steel: Including stainless steel for maximum durability and corrosion resistance, and weathering steel (e.g., Corten) for its distinctive evolving patina.

- Copper and Bronze: Chosen for their unique aesthetic qualities, rich colors, and the natural patination process that occurs over time.

- Zinc: Offers long-lasting durability and develops a protective, aesthetically pleasing patina.

These metals can be further treated with finishes like powder coating, anodizing, or PVDF coatings to enhance durability, provide color, and increase resistance to environmental factors.

Key Benefits

- Aesthetic Versatility: Perforations allow for an extensive range of visual expressions, from subtle textures to intricate graphic patterns, offering architects significant design freedom.

- Light Modulation and Ventilation: Panels can be designed to diffuse natural daylight, reducing glare and the need for artificial lighting, while also facilitating natural ventilation.

- Solar Shading and Energy Efficiency: Effectively acts as a solar screen (brise-soleil), reducing solar heat gain, which can lead to lower energy consumption for cooling and improved occupant comfort.

- Durability and Low Maintenance: Metals are inherently robust materials, resistant to impact, weathering, and pests, resulting in a long service life with minimal maintenance requirements.

- Privacy and Views: The density and size of perforations can be tailored to provide varying degrees of privacy from external viewpoints while still permitting outward visibility for occupants.

- Acoustic Performance: Depending on the perforation pattern, panel thickness, and any backing materials, perforated facades can contribute to sound absorption and reduction of noise pollution.

- Lightweight Cladding Solution: Compared to some traditional facade materials, perforated metal can be a lighter option, potentially reducing structural load requirements.

Common Applications

Perforated metal facades are extensively used across various building types:

- Commercial and office buildings

- Residential complexes and multi-storey apartments

- Parking structures (for screening and ventilation)

- Educational and institutional facilities

- Retail centers and showrooms

- Public transportation hubs

- Renovation and recladding of existing buildings

Design and Installation Considerations

Successful implementation of a perforated metal facade requires careful planning:

- Pattern Design: The size, shape, spacing (pitch), and overall percentage of open area of the perforations are critical to achieving the desired aesthetic and functional outcomes (light, airflow, privacy). Custom patterns are frequently employed.

- Material and Finish Selection: The choice of metal, thickness, and finish must align with project budget, aesthetic goals, structural demands, and local environmental conditions (e.g., coastal or industrial areas).

- Structural Engineering: Panels and their support systems must be engineered to withstand wind loads, thermal expansion/contraction, and other relevant structural forces. The fixing methodology is crucial for safety and longevity.

- Integration with Building Envelope: Consideration must be given to how the facade integrates with other building components such as windows, insulation, waterproofing membranes, and lighting systems.

- Visual Impact (Day and Night): The appearance can change dramatically with light conditions. Backlighting or integrated lighting can create striking nighttime effects.

- Maintenance Access: While low maintenance, provisions for cleaning or inspection should be considered if necessary.