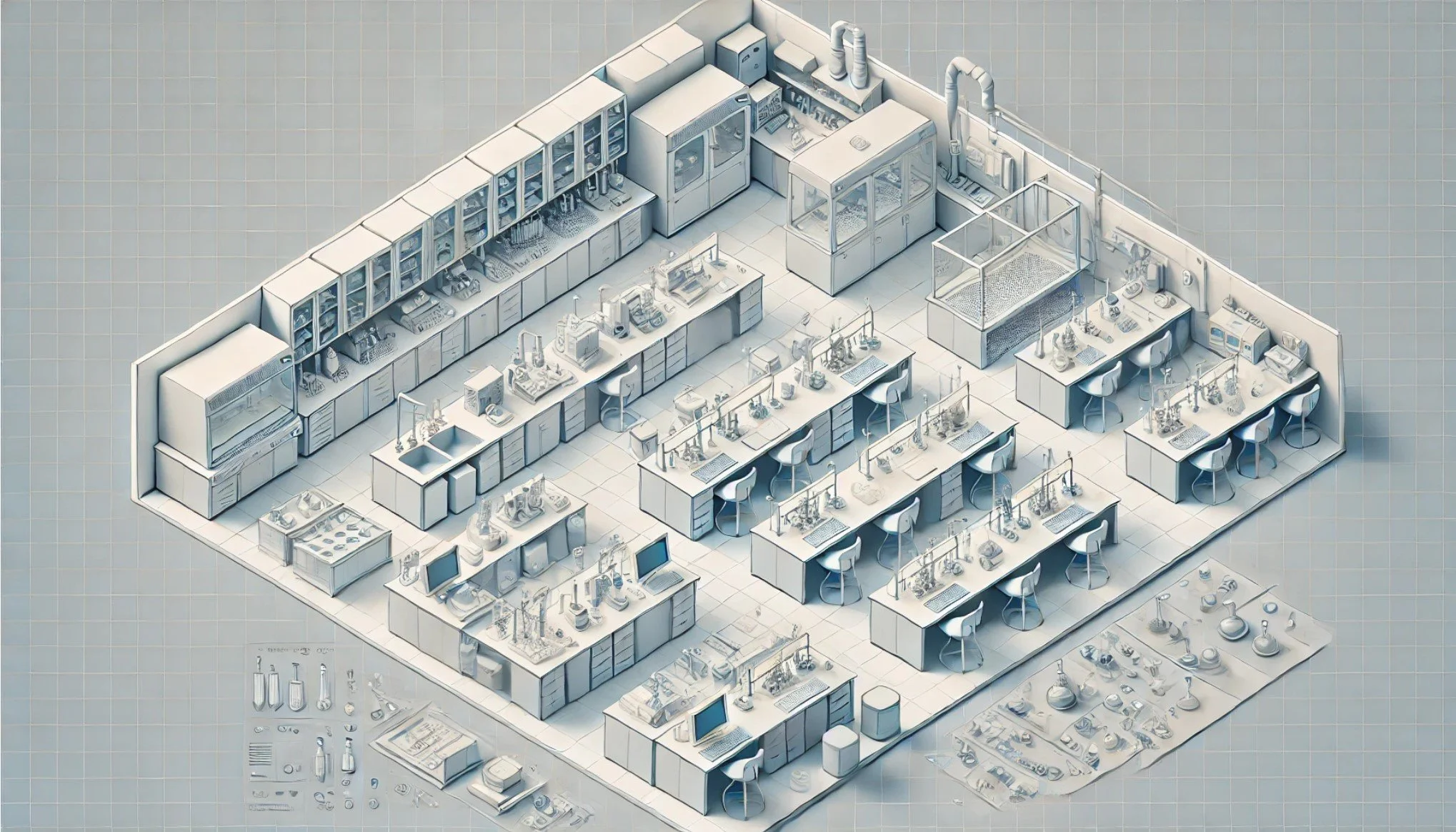

Effective laboratory architecture layout planning demands a strategic integration of scientific workflows, safety protocols, and future adaptability. Here are core principles for building high-performing science spaces:

Foundational Planning Principles

Workflow Optimization: Map primary processes (specimen prep, analysis, storage) to minimize transit distance & crossover between clean/dirty or hazardous/non-hazardous zones. Implement clear unidirectional flow where critical.

Safety Integration: Prioritize chemical/biological containment zones, emergency equipment accessibility, and ergonomic design. Position fume hoods, biosafety cabinets, and eyewash/showers strategically, ensuring clear egress paths.

Flexibility & Scalability: Design modular lab benches, mobile casework, and adaptable service spines (power, data, gases, vacuum) to accommodate evolving research needs and equipment upgrades. Utilize demountable partitions.

Zoning & Spatial Organization

Establish distinct zones based on function and hazard level:

- Support Zones: Dedicate areas for equipment (autoclaves, glasswashers), chemical storage (ventilated cabinets), and waste handling, separated from primary lab benches.

- Controlled Environment Zones: Isolate vibration-sensitive equipment (SEM, TEM), constant temperature/humidity rooms (tissue culture), or cleanrooms with appropriate access control & construction.

- Collaboration & Write-Up Zones: Integrate adjacent, separated areas for computation, documentation, and team interaction to minimize distractions in wet lab areas.

Equipment & Utility Planning

Critical Equipment Placement: Position heavy or vibration-generating equipment (ultracentrifuges, -80°C freezers) on ground floors or structurally reinforced slabs. Consolidate shared, high-demand instruments.

Utility Distribution: Employ modular overhead service carriers or accessible vertical service chases for utilities. Ensure adequate redundancy for essential services like compressed air, vacuum, and critical power. Clearly label all shutoff valves.

HVAC Strategy: Size systems for high ventilation rates required by fume hoods. Zone air handling based on heat load and contamination risk. Implement VAV controls and consider energy recovery.

Sustainability Considerations

- Incorporate high-efficiency HVAC systems, low-flow fume hoods, and lab equipment with low standby power.

- Specify durable, low-maintenance finishes resistant to chemicals and abrasion.

- Maximize natural light where compatible with instrumentation needs.

Enhancing User Experience

Ergonomics: Design adjustable-height benches, optimal shelf/cabinet heights, and comfortable task lighting to reduce physical strain.

Visual Oversight: Incorporate interior windows or open sightlines between zones to improve supervision, safety monitoring, and collaboration.

Acoustics: Address noise from specialized equipment with sound-absorbing materials and spatial buffering.

Successful lab planning requires early, collaborative engagement between scientists, EH&S personnel, facilities managers, and experienced lab architects to rigorously balance operational efficiency, safety compliance, and long-term adaptability.