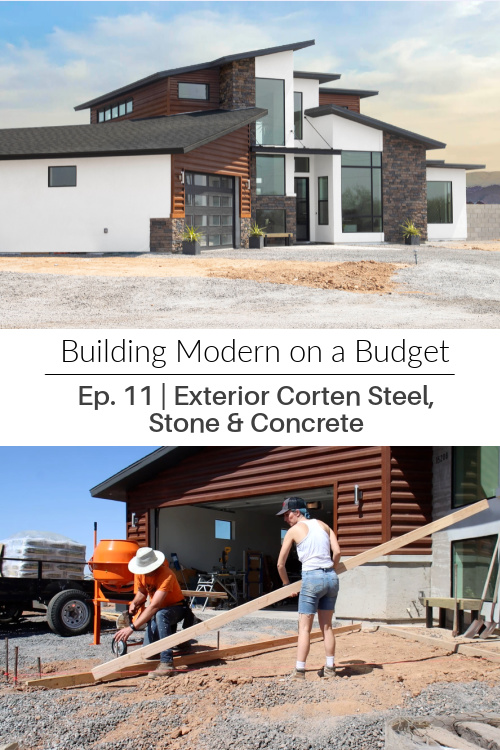

Corten steel architecture offers a striking aesthetic and inherent durability, but its cost requires careful consideration. Understanding the factors involved is crucial for accurate budgeting.

Corten Steel Cost Factors

- Material Grade & Thickness: Genuine ASTM A606 Corten costs significantly more than standard steel. Prices fluctuate based on global steel markets, thickness (gauges), and finish (mill finish or pre-weathered). Expect premium pricing over conventional structural steel.

- Fabrication Complexity: Cutting, bending, welding Corten demands specialized equipment and skilled labor. Intricate designs, complex shapes, and tight tolerances increase fabrication time and costs substantially.

- Scale & Volume: Larger projects benefit somewhat from economies of scale in material purchasing. However, complexity often outweighs simple volume savings.

- Transportation & Handling: Corten sheets/plates are heavy. Transportation costs and careful handling requirements to prevent damage add expense.

- Installation Labor: Requires experienced crews familiar with Corten's properties (e.g., managing the initial rust runoff). Specialized welding techniques and rigging add labor hours.

- Details & Connections: Hidden structural supports, custom brackets, and specialized fasteners designed for Corten compatibility add hidden costs.

- Site Conditions: Difficult access, remote locations, or stringent site regulations increase installation time and expense.

Realistic Price Ranges

Providing exact figures is impossible due to variables, but current indicative ranges are:

- Basic Cladding/Facade: $35 - $75 per square foot. Covers simple vertical applications.

- Moderate Complexity (Screens, Canopies): $75 - $150+ per square foot. Includes sculptural elements, multi-plane structures.

- High Complexity (Structural Elements, Sculptures): $150 - $300+ per square foot. Significant custom fabrication and engineering.

Remember: These are material + fabrication + installation costs. Engineering, permits, foundations, and project management are additional.

Corten vs. Alternatives

- Vs. Painted Steel: Corten is 1.5x - 3x the upfront cost, but eliminates repainting cycles. Long-term savings potential depends on maintenance costs of alternatives.

- Vs. Zinc/Aluminum: Similar premium positioning, sometimes less than Corten for basic forms, but aesthetics differ significantly.

- Vs. Stainless Steel: Certain architectural grades of stainless can be comparable or even exceed Corten pricing.

Essential Cost-Saving Tips

- Get Detailed Quotes: Insist on itemized bids breaking down material, fabrication, labor, engineering. Avoid vague lump sums.

- Optimize Design: Simplify complex geometries. Minimize unique parts. Plan efficient nesting of shapes to reduce material waste.

- Material Sourcing: Discuss options with fabricators – pre-weathered vs. natural weathering, standard gauges vs. custom.

- Fabricator Selection: Choose shops with proven Corten experience. Their expertise prevents costly mistakes and rework. Get references.

- Plan for Runoff: Design details managing the initial iron oxide runoff protect surrounding surfaces and avoid costly damage/cleaning. Factor this in.

- Value Engineering: Work with your architect and fabricator early to find areas where standard details or alternative materials could be used in non-critical areas without sacrificing the design intent.

- Get Multiple Bids: Essential for market comparison, but prioritize qualifications over the absolute lowest bid.