An industrial pumphouse is a dedicated facility designed to house and protect pumps and associated mechanical and electrical equipment. Its primary role is the controlled movement of fluids—such as water, chemicals, wastewater, or slurries—to support various industrial processes, utility services, or safety systems.

Core Functions and System Integration

The core function of an industrial pumphouse is to provide the necessary hydraulic energy (pressure and flow rate) to a fluid system. This involves more than just the pumps themselves; it's an integrated system typically comprising:

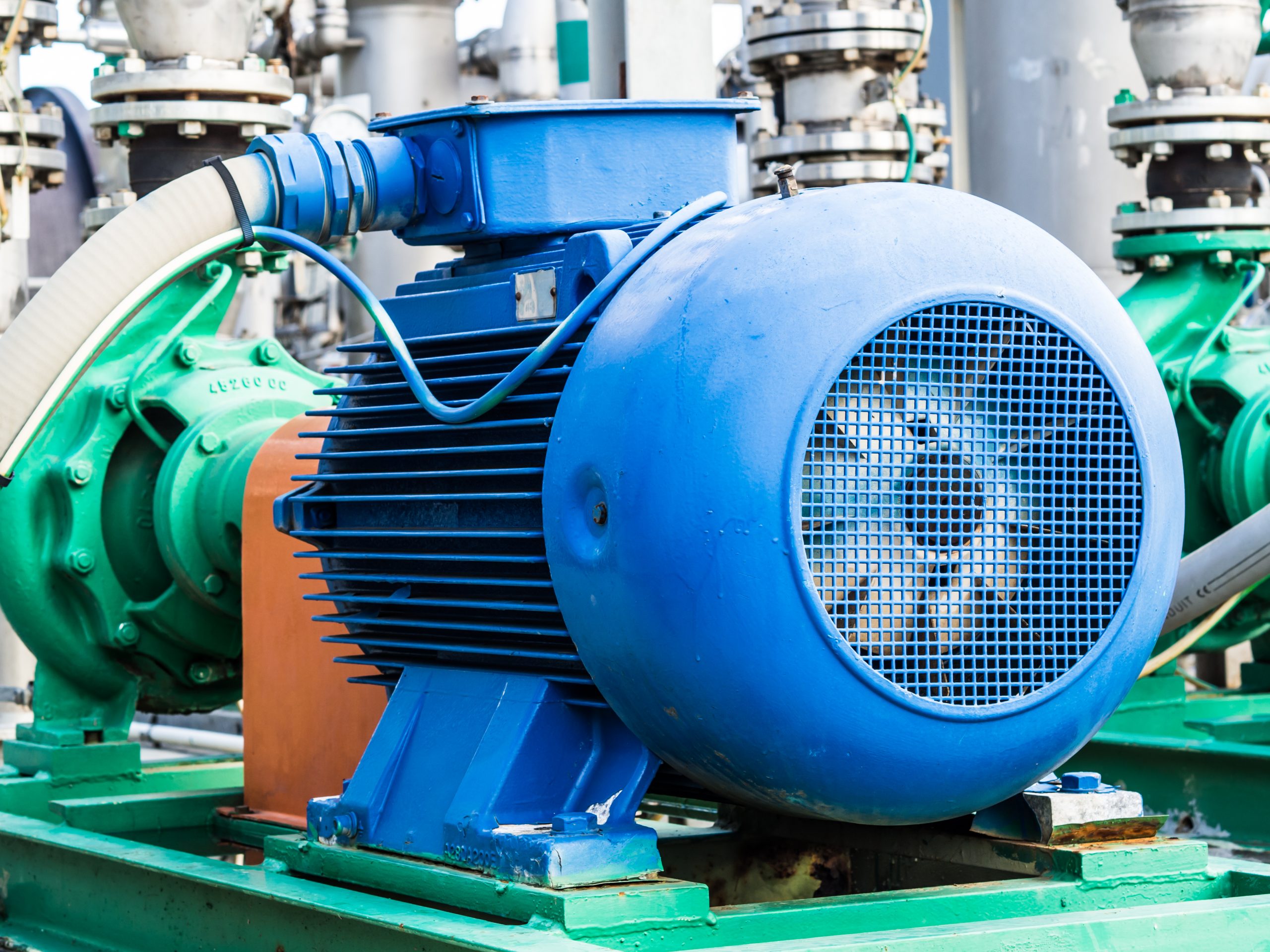

- Pumping Units: One or more pumps, selected based on fluid type, required head, flow rate, and efficiency. Common types include centrifugal, positive displacement, and submersible pumps.

- Prime Movers: Electric motors are predominant, though internal combustion engines or turbines may be used in specific scenarios. Variable Frequency Drives (VFDs) are often incorporated for speed control and energy optimization.

- Piping and Valving: Suction and discharge piping, along with isolation valves (gate, butterfly), control valves (globe, ball), check valves (to prevent backflow), and pressure relief valves.

- Control and Instrumentation: Motor Control Centers (MCCs), Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and sensors for pressure, flow, level, temperature, and vibration. These allow for automated operation, monitoring, and fault detection.

- Auxiliary Systems: May include ventilation (HVAC), sump pumps for drainage, lifting equipment (hoists, cranes) for maintenance, fire detection and suppression systems, and power backup systems.

Key Design and Operational Considerations

Effective pumphouse design and operation are critical for reliability, safety, and efficiency. Key considerations include:

- Process Requirements: Ensuring pumps are correctly sized for the application's demands, considering Net Positive Suction Head (NPSH) requirements to prevent cavitation.

- Reliability and Redundancy: Often designed with duty/standby pump configurations to ensure continuous operation during maintenance or failure of a primary unit.

- Energy Efficiency: Selection of high-efficiency pumps and motors, optimal pipe sizing to minimize frictional losses, and the use of VFDs.

- Safety: Adherence to relevant codes and standards, proper electrical grounding, hazardous area classification (if applicable), emergency stop systems, and adequate access/egress.

- Maintainability: Layout designed for easy access to equipment for inspection, maintenance, and repair. Adequate space for component removal and replacement.

- Environmental Protection: Measures for noise abatement, spill containment, and managing any potential leaks or discharges.

- Automation and Monitoring: Implementing systems for remote monitoring and control can improve operational efficiency and allow for predictive maintenance.

Applications Across Industries

Industrial pumphouses are indispensable in a multitude of sectors:

- Water and Wastewater: Municipal water supply, wastewater treatment plants (influent, effluent, sludge pumping), stormwater management.

- Manufacturing: Cooling water circulation, process fluid transfer, boiler feedwater systems.

- Oil and Gas: Pipeline booster stations, crude oil transfer, produced water handling, refinery processes.

- Chemical Processing: Transfer of various chemicals, dosing systems.

- Power Generation: Cooling water intake and circulation, condensate extraction, ash handling.

- Mining: Dewatering, slurry transport, process water supply.

- Fire Protection: Dedicated firewater pumphouses maintaining pressure in fire hydrant and sprinkler systems.

In essence, the industrial pumphouse is a vital infrastructure component, engineered to ensure the dependable and efficient handling of fluids, which is fundamental to the operation, safety, and productivity of numerous industrial facilities.