Cross-Laminated Timber (CLT) and traditional building methods (like concrete block or timber framing) represent fundamentally different approaches. Understanding their key distinctions is crucial for informed project decisions.

Material & Structural System

CLT: Engineered wood panels formed by gluing layers of solid lumber at right angles. Functions as large-format, load-bearing wall, floor, and roof panels. Offers high dimensional stability and acts as a monolithic structural shell.

Traditional Build (e.g., Timber Frame): Typically employs a linear framing system (studs, joists, rafters) requiring supplementary sheathing (OSB, plywood) and often cavity insulation. Concrete block relies on masonry units and mortar for structure.

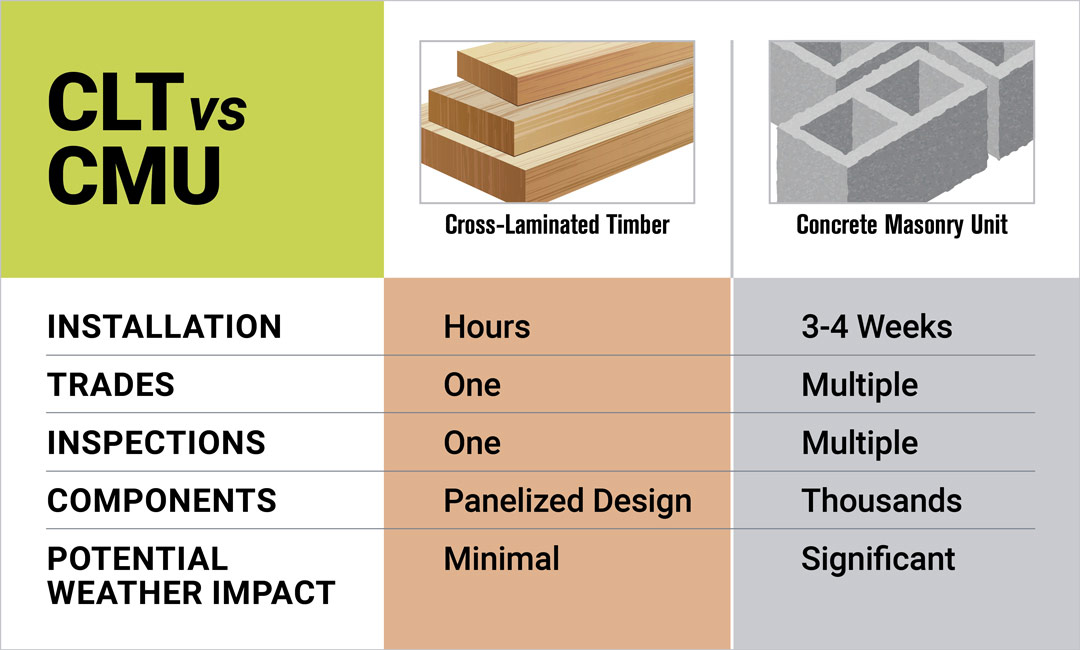

Construction Process & Speed

CLT:

- Predominant factory prefabrication: Panels are CNC-cut to precision off-site.

- Rapid on-site assembly: Crane erection connects large panels quickly.

- Reduced labor and trades on-site: Faster enclosure, less susceptible to weather delays.

- Minimal waste: Optimized off-site cutting.

Traditional Build:

- Primarily stick-built on-site: Sequential assembly of numerous components.

- Longer construction timeline: More weather exposure, numerous trades involved sequentially.

- Higher potential for on-site waste and errors.

Building Performance

Thermal Efficiency: Both systems can achieve high performance, but CLT panels inherently provide excellent airtightness due to minimal joints. Traditional builds require meticulous detailing for similar airtightness.

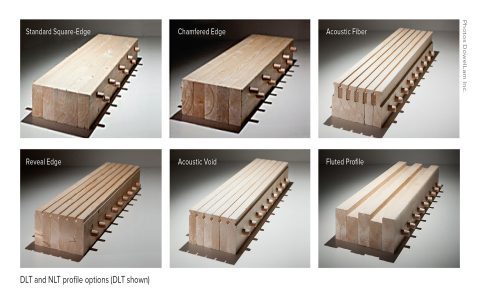

Acoustic Performance: CLT offers superior inherent mass for impact sound insulation. Airborne sound performance depends on system design in both.

Fire Resistance: CLT chars predictably, maintaining structural integrity when designed correctly. Concrete is non-combustible. Timber framing relies heavily on protective cladding.

Seismic Resilience: CLT's stiffness and ductile connections provide excellent seismic performance, comparable or superior to well-detailed traditional systems.

Sustainability & Environmental Impact

CLT:

- Significant carbon storage: Sequestered CO2 in wood remains locked in.

- Lower embodied energy: Compared to steel and concrete.

- Renewable resource: Sustainably sourced timber.

Traditional Build (especially concrete/block):

- Higher embodied carbon: Cement production is energy-intensive.

- Often requires non-renewable materials (steel, aggregate).

- Timber framing has lower embodied carbon than concrete/block but typically requires more timber volume than CLT for equivalent structure.

Design Flexibility & Aesthetics

CLT: Enables long spans and open-plan designs. Panels have an inherent aesthetic often left exposed internally. Precision limits on-site modification.

Traditional Build: Highly adaptable for complex shapes and alterations during construction. Aesthetic finishes are generally added layers over the structure.

Cost Considerations

CLT: Higher material cost per unit area currently. Savings often realized through faster construction speed (reduced finance/overheads), lower labor requirements, and less waste disposal.

Traditional Build: Generally lower material costs initially. Total project cost highly dependent on labor efficiency, project duration, and complexity.

Key Decision Factors

- Project Goals: Speed-to-market, sustainability targets, design aspirations.

- Budget: Upfront vs. whole-project cost.

- Site Logistics: Access for large panels, on-site storage.

- Local Expertise & Supply: Availability of experienced CLT contractors and manufacturers.

- Regulatory Environment: Building codes often evolving for CLT.