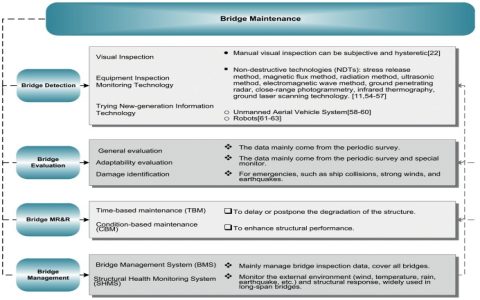

Effective bridge maintenance is essential to prevent structural failures and avoid expensive repairs, prolonging service life while enhancing safety.

Regular Inspections

Schedule comprehensive quarterly inspections to identify issues early, focusing on cracks, corrosion, and foundation stability; use drones or sensors for hard-to-reach areas to detect weaknesses proactively.

Clean Drainage Systems

Clear debris from drains, scuppers, and gutters monthly to prevent water accumulation and erosion, which significantly reduces deterioration risks in joints and supports during heavy rainfall.

Corrosion Prevention

Apply protective coatings every 3-5 years and repair exposed rebar promptly; monitor for rust using ultrasonic testing to extend material durability and avoid costly replacements.

Load Capacity Monitoring

Track vehicle weights and traffic volumes through sensors or manual logs; reinforce overload-prone areas with steel girders to maintain safety standards and prevent structural damage from excessive stress.

Timely Minor Repairs

Address small cracks or surface issues immediately during inspections; prioritize quick fixes like patching or sealing over deferred actions to minimize escalation into major reconstruction projects.

Consistently implementing these strategies optimizes maintenance budgets, ensures compliance with regulations, and avoids unforeseen failures.