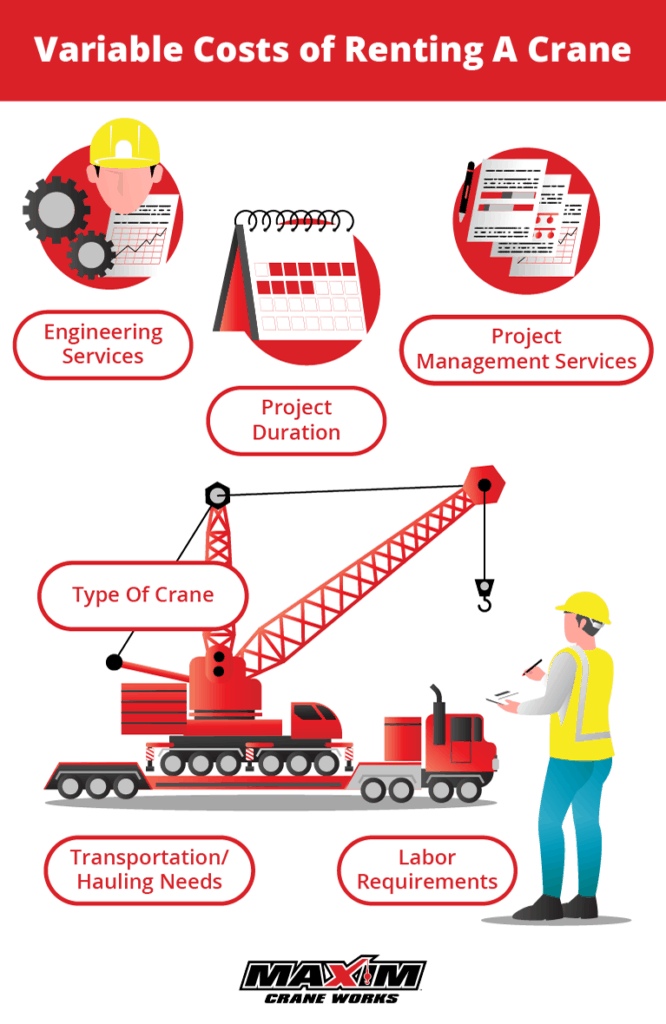

Factors Driving Roots Crane Price Variations

Roots Crane costs vary significantly across the market, influenced by multiple technical and economic factors. Price differences stem from equipment specifications, customization, and external elements such as supply chain dynamics and geographical location.

- Lifting Capacity and Size: Higher tonnage or larger boom lengths increase material and manufacturing expenses, directly raising purchase costs.

- Technology and Features: Models with automated controls or advanced safety systems command premium prices due to complex engineering and certifications.

- Material Quality and Durability: Units built with high-grade steel for harsh environments incur higher costs, while budget-friendly models may use standard materials.

- Customization Requirements: Tailored designs or specialized attachments add expenses, as they involve unique engineering and testing.

- Market Conditions: Fluctuations in raw material costs, demand-supply imbalances, or regional tariffs impact final pricing without altering core specifications.

These factors mean cost disparities of 15-50% are common even for similar crane types.

Comparing Popular Roots Crane Models

Understanding model differences clarifies cost variations, enabling informed decisions. Key specs like capacity and efficiency are critical for comparing expenses upfront and long-term.

- Basic Model (e.g., RC-100 Series): Lower cost with manual controls and 10-20 ton capacity; ideal for light industrial tasks but requires higher maintenance, leading to elevated lifetime expenses.

- Mid-Range Model (e.g., RC-300 Series): Moderate price offers semi-automated features and 30-50 ton capacity; improved energy efficiency reduces operational costs by 10-20% compared to basic models.

- Premium Model (e.g., RC-500 Series): Higher investment includes full automation and up to 100 ton capacity; reduced downtime and extended lifespan lower total ownership costs over time.

Cost-efficiency varies; for instance, premium models may yield 25% savings in heavy-duty applications despite higher initial prices.

Navigating Cost-Effective Purchases

Focus on total cost of ownership rather than purchase price alone. Evaluate warranty, maintenance cycles, and fuel consumption using manufacturer data to select models aligning with your operational needs and budget constraints.