Key Factors Affecting Train Design Costs

Understanding the primary drivers of train design expenses is crucial for effective budget management in railway projects. These factors influence overall costs by affecting resources, timelines, and compliance requirements.

Design Complexity

The intricacy of the train's engineering, including aerodynamics, ergonomics, and system integration, requires advanced CAD modeling and specialized expertise, escalating labor and software expenses.

Material Selection

High-performance materials like lightweight composites or corrosion-resistant alloys increase upfront costs due to sourcing challenges and specialized handling during design validation.

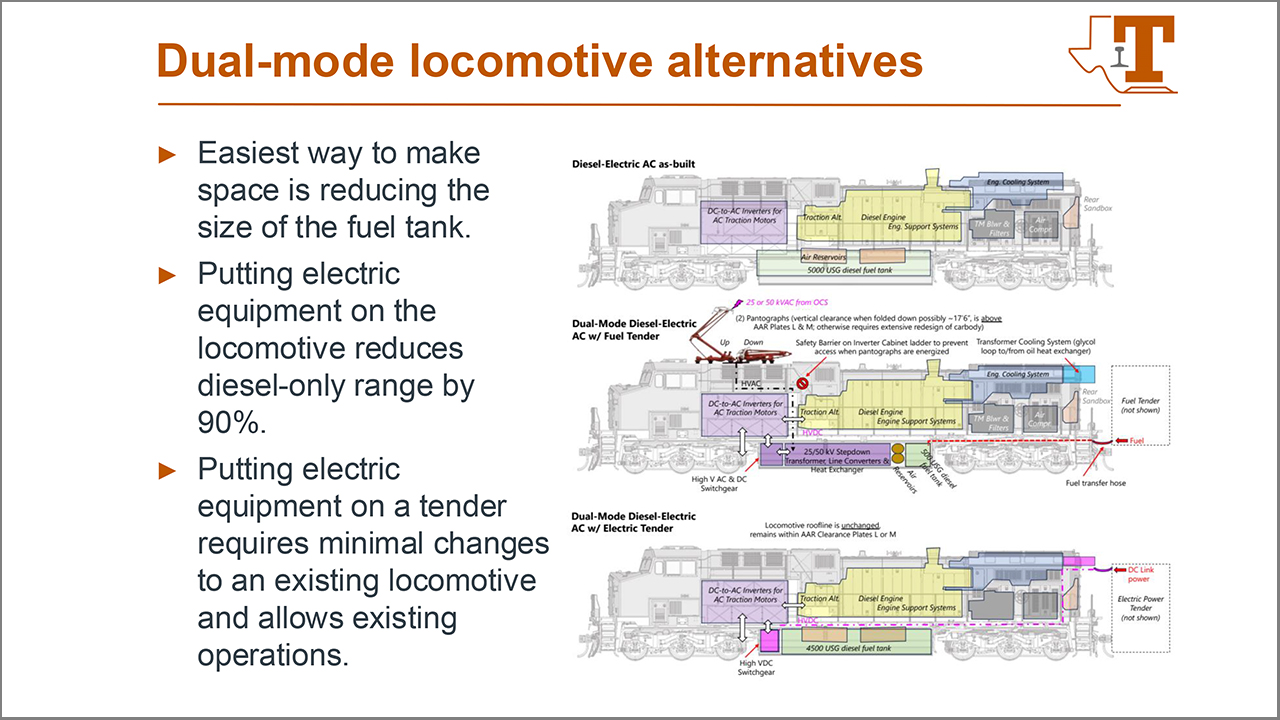

Regulatory Compliance

Meeting strict international standards, such as FRA or EU directives, involves exhaustive testing, documentation, and safety certifications, adding substantial layers to the design phase budget.

Technology Integration

Incorporating innovations like AI-driven simulations or predictive maintenance systems raises development costs but can optimize long-term operational efficiency.

Customization Level

Bespoke features and unique specifications demand tailored design solutions, increasing resource allocation and extending timelines compared to modular approaches.

Project Timeline

Accelerated schedules often necessitate overtime work, expedited supplier deliveries, and premium services, inflating labor and overhead expenditures.

Expertise and Labor Costs

Skilled designers, engineers, and consultants command variable fees based on experience and geographic location, directly impacting the project's human resource budget.

Prototyping and Testing

Building physical prototypes and conducting rigorous tests for durability and safety validation are essential, yet costly, steps in ensuring design reliability.