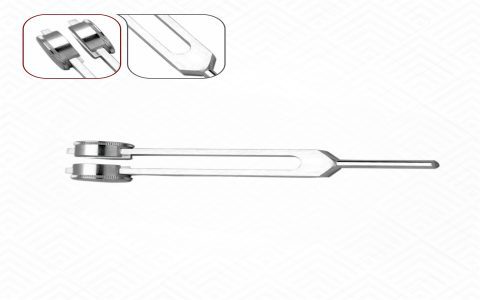

A vibrating fork is a mechanical resonator, typically U-shaped with two prongs (tines), designed to vibrate at a specific, constant frequency when energized. Its operation relies on the principles of elasticity and inertia.

Core Principle

When a vibrating fork is struck or otherwise excited, its tines oscillate symmetrically, moving alternately towards and away from each other. The natural frequency of this vibration is primarily determined by the tines' length, mass, cross-sectional shape, and the material's Young's modulus. This consistent frequency makes it a reliable reference source.

Key Characteristics

- Precise Resonant Frequency: Vibrates at a highly stable and accurately defined frequency.

- Pure Tone Generation: Produces a sound with minimal overtones, resulting in a clear, pure tone when used acoustically.

- Durability and Stability: Typically made from robust materials like steel or aluminum alloys, ensuring long-term stability of frequency, especially in controlled environments.

- Sensitivity to Environment: In sensor applications, its vibration characteristics (frequency, amplitude, damping) are sensitively affected by the surrounding medium (e.g., liquid, solid, gas properties).

Applications

Vibrating forks are utilized across various fields due to their reliable oscillatory behavior.

Musical Tuning

The classic application is the tuning fork, used as a standard pitch reference (e.g., A4 = 440 Hz) for tuning musical instruments and voices.

Industrial Process Measurement

In industrial settings, vibrating forks serve as robust sensors for:

- Level Detection: Used as point level switches for liquids and bulk solids. The fork's vibration dampens or its frequency shifts upon contact with the material, triggering an output signal.

- Density Measurement: The resonant frequency of a fork immersed in a fluid changes predictably with the fluid's density, allowing for continuous density monitoring.

- Viscosity Measurement: The damping of the fork’s oscillation in a fluid is correlated with the fluid's viscosity, forming the basis for in-line viscometers.

Medical Diagnostics

In otolaryngology, tuning forks are employed in hearing tests, such as the Rinne test and Weber test. These tests help differentiate between conductive and sensorineural hearing loss by assessing the patient's perception of sound conducted through air and bone.